1. Proizvod je gotovview

The Sealey IS160 is a 60mm impact socket designed for heavy-duty applications. It features a 1" square drive and is constructed from Chrome Molybdenum steel, ensuring durability and strength. The socket is finished with a phosphate coating for enhanced corrosion resistance. Its WallDrive design grips the flats of fasteners, reducing the risk of rounding off corners.

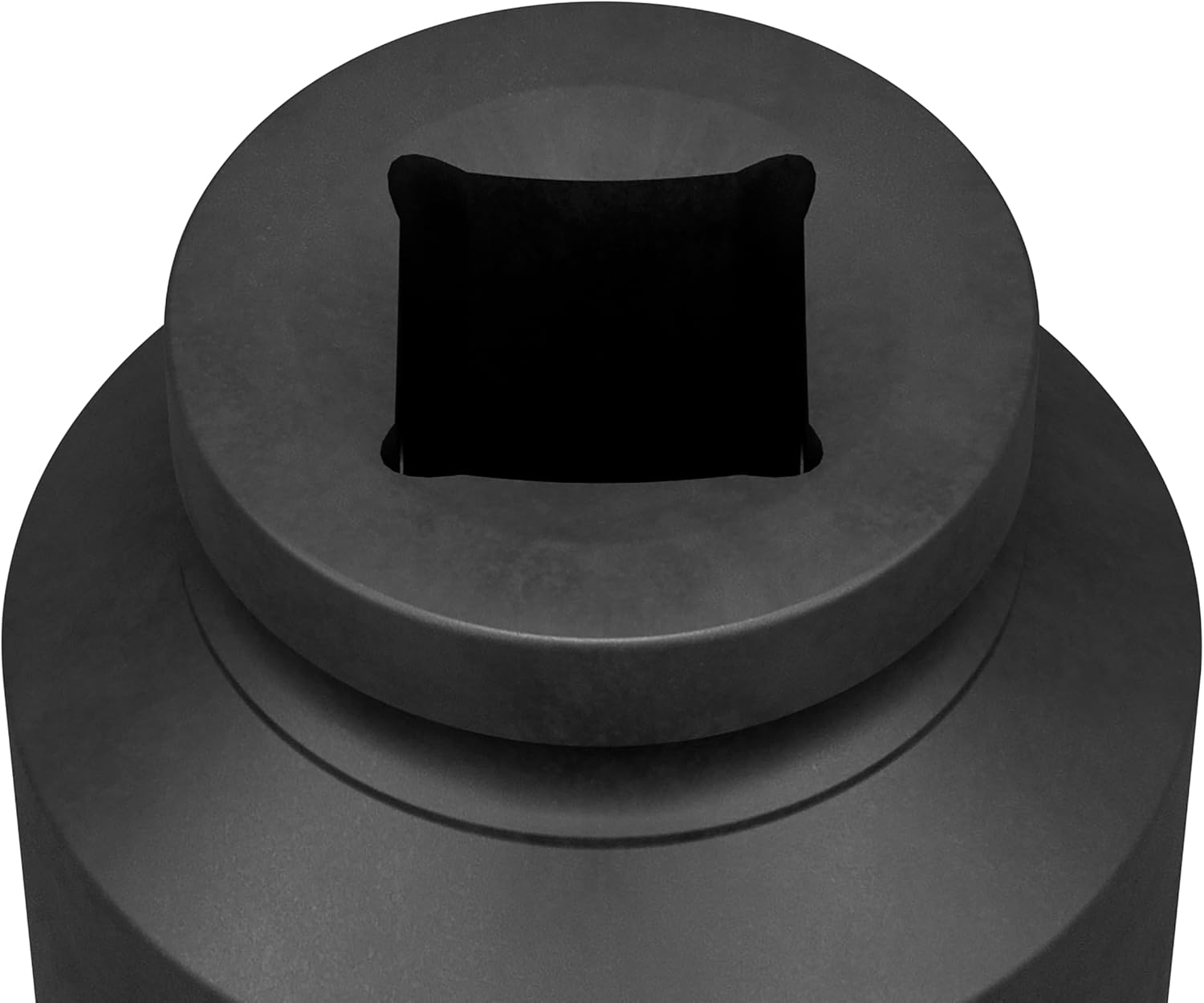

Image 1.1: The Sealey IS160 60mm impact socket, showing its robust construction and black phosphate finish.

Ključne karakteristike:

- Veličina pogona: 1" kvadrat

- Veličina utičnice: 60 mm

- Materijal: Chrome Molybdenum Steel

- Završiti: Phosphate for corrosion resistance

- Dizajn: WallDrive for improved grip and reduced fastener damage

- Izdržljivost: Hardened and tempered for added strength

Image 1.2: Illustration of the WallDrive design, highlighting its ability to grip fastener flats for increased torque and reduced rounding.

Image 1.3: Details on the benefits of the phosphate finish, including corrosion resistance and improved wear resistance.

2. Postavljanje

This section outlines the proper procedure for attaching the impact socket to a compatible impact wrench.

2.1 Sigurnosne mjere opreza

- Always wear appropriate personal protective equipment (PPE), including safety glasses, when using impact tools.

- Ensure the impact wrench is disconnected from its power source (air or electric) before attaching or detaching sockets.

- Verify that the socket size matches the fastener size to prevent damage to both the socket and the fastener.

- Use only impact-rated sockets with impact wrenches. Standard chrome sockets are not designed for impact use and can shatter.

2.2 Attaching the Socket

- Select the correct 60mm impact socket for your application.

- Align the 1" square drive opening of the socket with the square drive anvil of your impact wrench.

- Push the socket firmly onto the anvil until it clicks into place. Many impact wrenches have a detent pin or friction ring to secure the socket. Ensure the socket is fully seated and secure.

- Gently pull on the socket to confirm it is securely attached and will not detach during operation.

Slika 2.1: Krupni plan view of the 1" square drive opening on the socket, where it connects to an impact wrench.

3. Upute za rad

This section provides guidelines for the safe and effective use of the Sealey IS160 impact socket.

3.1 Opća uporaba

- Once the socket is securely attached to the impact wrench, position the socket squarely onto the fastener (nut or bolt head).

- Ensure the socket is fully engaged with the fastener before activating the impact wrench. Misalignment can lead to fastener damage or socket wear.

- Apply steady, firm pressure to the impact wrench to keep the socket engaged with the fastener.

- Activate the impact wrench in short bursts initially to assess the fastener's resistance, especially when loosening tight fasteners.

- Avoid excessive impacting once the fastener is loose or tight, as this can over-tighten, strip threads, or damage the socket/fastener.

3.2 Torque Considerations

While impact sockets are designed for high torque applications, it is crucial to use a torque wrench for final tightening to achieve precise torque specifications, especially in critical applications. Impact wrenches are primarily for loosening and initial tightening.

4. Održavanje

Proper maintenance extends the life of your Sealey IS160 impact socket and ensures continued performance.

4.1 Čišćenje

- After each use, wipe the socket clean with a dry cloth to remove dirt, grease, and debris.

- For stubborn grime, use a mild degreaser and a brush, then wipe dry immediately.

- Ensure the socket is completely dry before storage to prevent rust, especially in humid environments.

4.2 Skladištenje

- Store the socket in a dry environment, away from moisture and corrosive chemicals.

- Keep sockets organized in a socket tray or toolbox to prevent loss and damage.

- Avoid storing sockets where they can be exposed to extreme temperatures.

4.3 Inspekcija

- Regularly inspect the socket for signs of wear, cracks, or deformation.

- Pay close attention to the square drive opening and the hex opening for any signs of rounding or damage.

- If any significant damage is observed, discontinue use immediately and replace the socket to prevent injury or further damage to fasteners.

5. Rješavanje problema

This section addresses common issues that may arise during the use of the impact socket.

Socket Not Fitting Fastener

- Izdati: The 60mm socket does not fit over the fastener.

- Otopina: Verify that the fastener size is indeed 60mm. Measure the fastener if unsure. Ensure there is no obstruction or debris preventing the socket from seating fully.

Socket Slipping or Rounding Fastener

- Izdati: The socket slips on the fastener, or the fastener's corners are rounding off.

- Otopina: Ensure the socket is fully seated and square on the fastener before applying power. Inspect the socket's hex opening for wear or damage. If the fastener is already partially rounded, the WallDrive design may still grip, but severe rounding may require a specialized fastener extractor.

Socket Damaged

- Izdati: The socket shows cracks, chips, or deformation.

- Otopina: Discontinue use immediately. Damaged sockets can be dangerous and may fail catastrophically. Replace the socket. Ensure you are using the correct type of socket (impact-rated) for your application.

6. Specifikacije

| Značajka | Detalj |

|---|---|

| Marka | Sealey |

| Broj modela | IS160 |

| Veličina pogona | 1" kvadrat |

| Veličina utičnice | 60 mm |

| Materijal | Chrome Molybdenum Steel |

| Vrsta završetka | Phosphate Finish |

| Duljina stavke | 2.36 inča |

| Težina artikla | 3.96 funti |

| Broj komada | 1 |

7. Jamstvo

The Sealey IS160 Impact Socket is backed by a Lifetime Guarantee.

Image 7.1: Sealey Lifetime Guarantee emblem. Terms and conditions apply.

For full details regarding the terms and conditions of the Lifetime Guarantee, please refer to the official Sealey website or contact Sealey customer service. This guarantee typically covers manufacturing defects and material flaws under normal use.

8. Podrška

Should you require further assistance, have questions not covered in this manual, or need to make a warranty claim, please contact Sealey customer support.

- Proizvođač Webstranica: Visit the official Sealey webstranica za informacije o proizvodu, često postavljana pitanja i kontakt podatke.

- Služba za korisnike: Refer to your product packaging or the Sealey website for specific customer service contact information (phone, email).

When contacting support, please have your product model number (IS160) and any relevant purchase information ready.